Effective inventory management is critical for maintaining optimal stock levels and reducing costs. This guide explores 11 proven strategies to optimize inventory, from demand forecasting and safety stock to lean management practices. By adopting these methods, companies can improve efficiency, reduce excess stock, and ensure seamless operations within the supply chain.

And if some of those strategies may seem obvious, in practice, few companies apply them.

Video Tutorial: 11 proven Inventory Reduction Strategies

1) Implement Supply Chain KPIs

To improve any process in Supply Chain, you need first metrics to track your performance. Simply put, you cannot improve what you cannot track.

Implementing shared KPIs (Key Performance Indicators) throughout the company is essential to optimize inventory management. Be careful, though: too many KPIs are counterproductive. It is about finding the right balance.

I recommend 2 main Supply Chain KPIs:

Customer Availability Rate or Fill Rate

Knowing your actual customer service level is essential.

The Service Rate is about assessing if inventory levels meet customer demand.

If you manage a physical store, there is no way to know how much the demand is. Because the customer doesn’t order in advance, and doesn’t tell what he was looking for when he gets out of the store. Then, a good way to estimate the service Rate is to use the Availability Rate: is the product available in shelves or not ?

Otherwise, if you know how many orders you have, you can calculate the Fill Rate: the percentage of successfully delivered orders. There are many ways to calculate this indicator, check my article on the matter: OTIF, DIFOT, Fill Rate: KPI Service Calculation & Formulas.

Inventory Turnover

The inventory turnover ratio is used to assess if the stock is excessive compared to the sales over a period. It answers the question “How many times does my stock turn over?”. Check my full article about this crucial KPI: Inventory Turnover ratio: Formulas & Calculation in Excel.

Using those two KPIs – Service Rate and Inventory Turnover – gives good visibility of inventory and service levels.

2) ABC Analysis (20/80 focus)

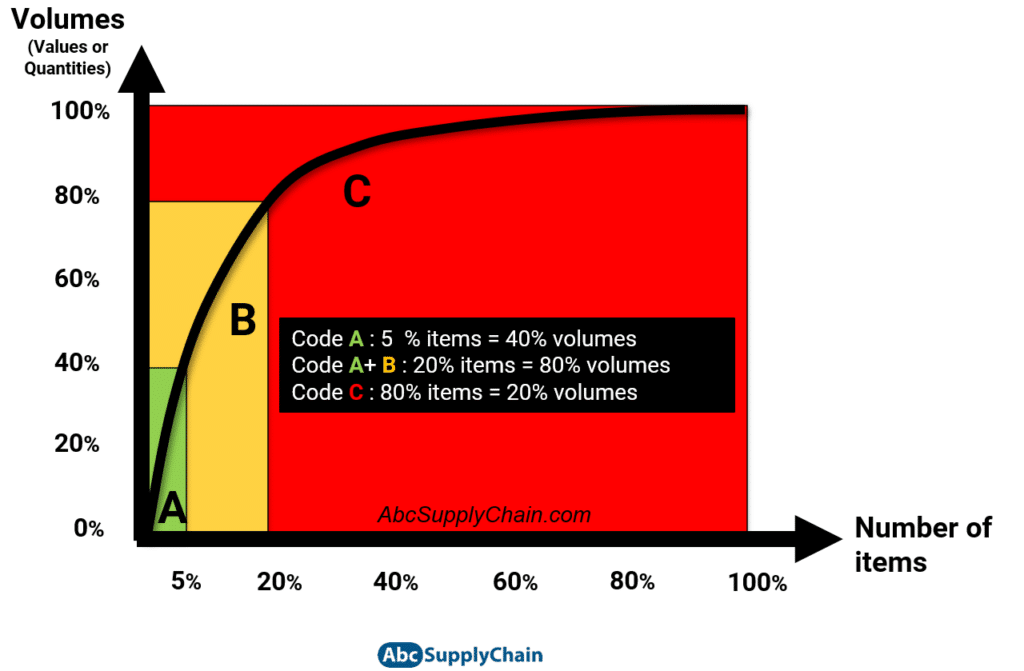

To optimize inventory, I always recommend focusing your energy, time, and money on the “20/80”: 80% of the results are produced by 20% of the causes.

This is the main principle of the ABC Analysis in Inventory Management. It is about classifying the few items that will make the most of your business (A products), and the many items that make a small part of your business (C products). B products are in-between.

See our step-by-step tutorial in Excel here: ABC Analysis in Excel

3) Clean Slow and Obsolete Stocks (SLOB)

One of the first actions to take to optimize inventory is to identify Slow and Obsolete Stocks. I have been doing a lot of consulting for the past few years, and according to my experience, a lot of companies don’t have clear visibility over SLOB inventory, which penalizes them financially.

To identify the SLOB inventory, you must find the products with very few sales compared to their stock levels (low inventory turnover value or high days in inventory value).

We talk about big quantities of a few items that will never be liquidated unless you take specific actions:

- Identify obsolete stock (discontinued products, expired products)

- Identify slow movers (low selling items)

- Cancel current purchase orders. Sometimes companies forget to cancel automatic orders for discontinued products. If they are products you are still selling, you need to recalculate the replenishment with lower values (and you may still need to cancel all orders in the short term).

- Return products to the supplier. Try it if it is part of your supplier’s policy.

- Make promotions. And get in touch with your Marketing department if necessary.

- Cancel new products or postpone launching. You may have new collections planned to replace the current slow-moving stock, but you need to liquidate it first, or you will be overwhelmed.

- Make donations. Before thinking about destroying the products, you can donate the products to charitable contributions.

- Destroy the excess inventory. This is the worst-case scenario.

- Keep tracking your SLOB inventory and be proactive.

4) Accept shortages for low selling products

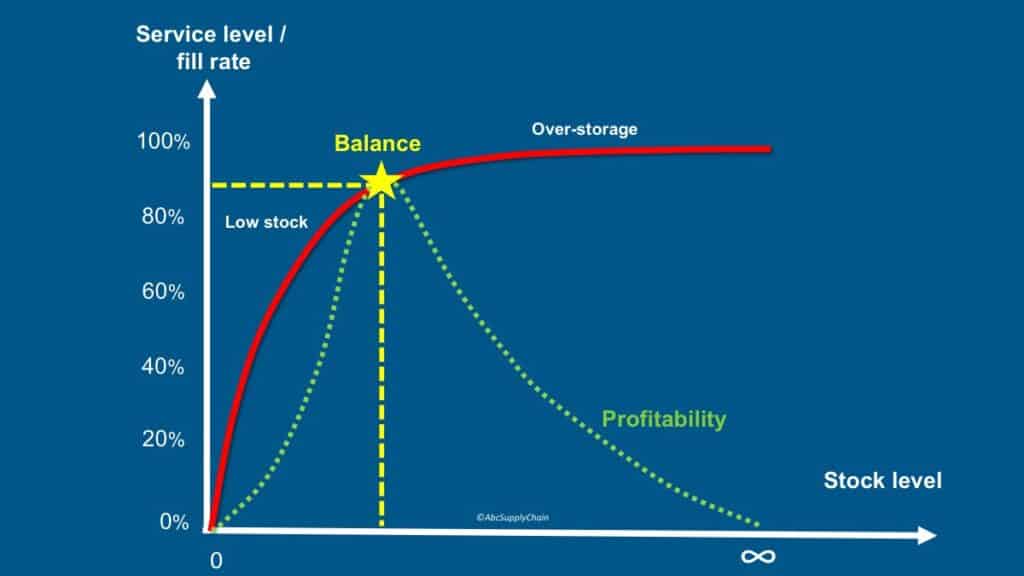

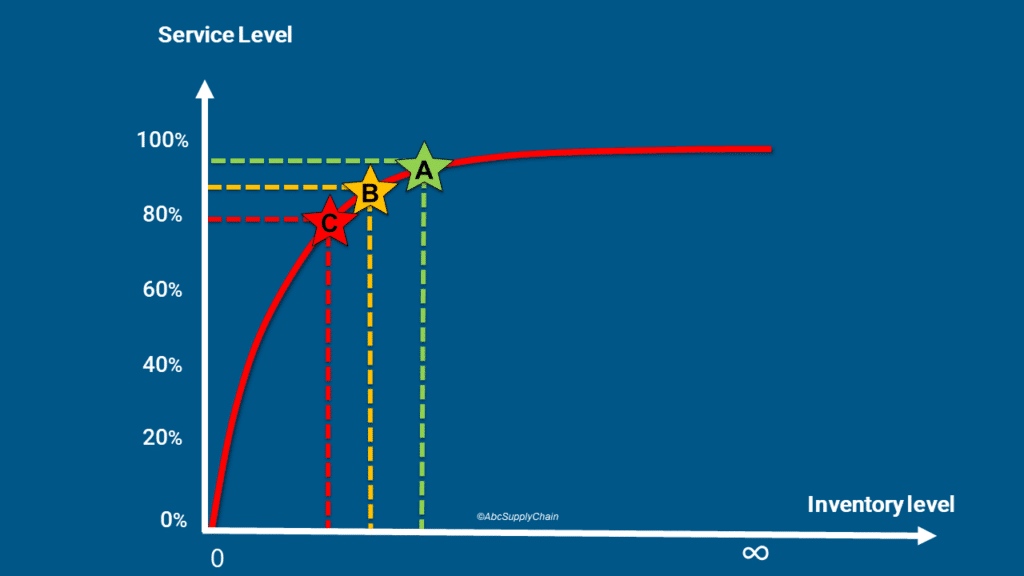

Keep in mind that you can never target a 100% service rate, as you would need infinite stock. High service can thus compromise your finance: but you can choose to maximize service for some products, and to accept out-of-stocks for others (yes, sometimes shortages are ok!)

As I stated before, Inventory Management is a chest game between Inventory and Service. You must find the right balance to optimize Inventory without compromising customer service. The idea is to target different service levels according to product classification.

For low selling items (or C codes), you might seek a lower service level, to lower your stock on a wide range of products.

5) Reduce the number of products

If your product offering is very diversified, it does not necessarily mean you will get high sales. Often, it is better to reduce the number of products you sell, as it will be easier to optimize inventory and maximize value delivery for your top products.

Apple is one of the best examples in the world. This company has managed to maintain a very small number of products (available in different colors and sizes) despite hundreds of billions of dollars in sales. Apple focuses all its time, energy, cash, and marketing on specific items. It is also much easier to manage inventory for Apple than for its competitor Samsung, for example.

6) Improve (or implement) your forecasts

Today, a lot of companies do not even have a forecast. It is never too late to start forecasting:

- Demand

- New Products

- Purchasing

- Replenishment

Again, I advise you to keep a 20/80 focus and to start forecasting your A & B codes first.

Then, make sure you track forecasting accuracy properly (see Forecast Accuracy formula: 4 Calculations in Excel). This is imperative to estimate the performance of your forecasts. Finally, optimize and automate the forecasting process.

7) Reduce your MOQ (Minimum Order Quantity)

Suppliers often have a minimum order quantity (MOQ), it is the smallest quantity the supplier is willing to sell. If the MOQ is very high compared to your forecast or sales quantities, this can be an issue: you will always be forced to order more than necessary.

For example, let’s say you plan to sell 100 pieces of a shoe for the year to come. Your supplier MOQ is 500 pieces. It means that, just by making one order, you will have 5 years of inventory for this product.

It might be less extreme in your case. Nevertheless, it illustrates how important it is to keep an eye on MOQ. To see which products have problematic MOQ, divide the MOQ by the average daily sales quantity of each product. This way, you get the days in Inventory for one order, and you can identify high values.

To reduce MOQ and optimize inventory, you have different options in order of priority:

- Negotiate with the supplier

- Optimize the container or truck

- Change supplier

- Replace/Remove product

8) Mitigate supply and demand uncertainty

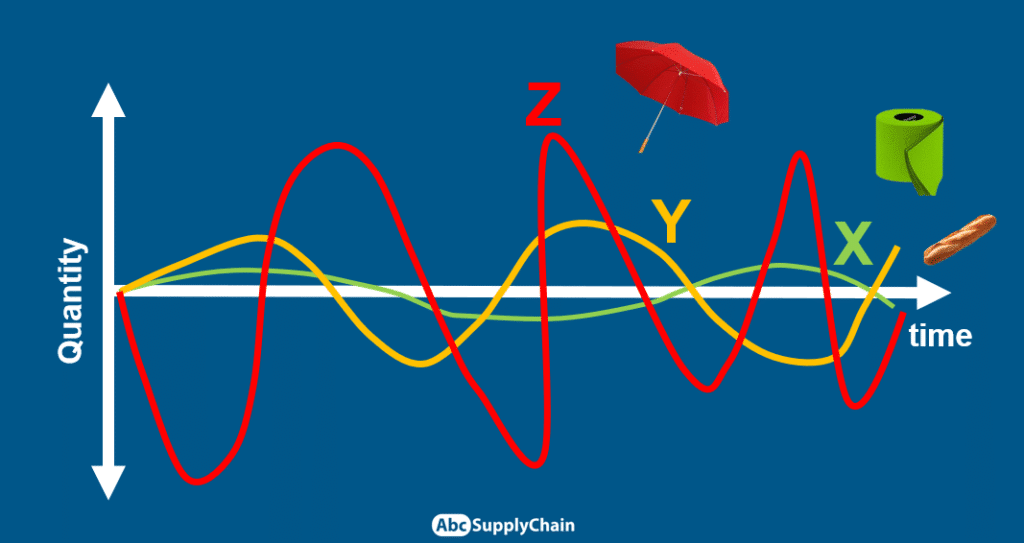

Products have different levels of demand uncertainty.

For example, there are stable products such as toilet paper, and others much more uncertain, such as umbrellas – which are sold only during rainy periods. You will probably have a better forecast quality on toilet paper than on the umbrella.

To see how to deal with demand uncertainty, have a look at my article ABC XYZ Analysis in Inventory Management: example in Excel.

The same applies for supply uncertainty or lead time uncertainty.

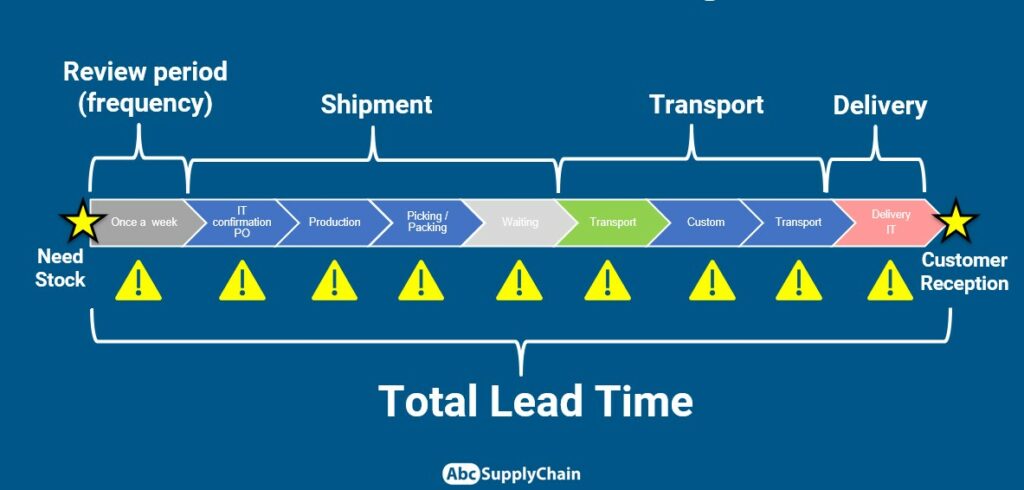

Indeed, there are many factors impacting the total lead time:

- Review period: how often you order

- IT confirmation delay / Purchase Order delays

- Production lead time

- Picking/Packing time in the warehouse or factory

- Waiting time before shipping

- Transportation time / transit time

- Customs

- Delivery time

Any hazard over one of those factors directly impacts the lead time, and so the risk of shortage or overstock.

One solution to cover against supply and demand uncertainty is to hold more stock (see Safety Stock Formula & Calculation: 6 best methods). But maintaining high stock levels is often a trick to hide the root causes of issues, and it will drive inventory costs higher. That’s why you need to mitigate hazards to optimize inventory: improve your forecasts, improve your communications with your supplier…

9) Reduce Lead time

As we saw above, the lead time is not just about the transport. It is the time between we need stock and the moment we receive it.

The longer the lead time is, the longer will be the replenishment cycles and so the safety stocks and quantities to order. That is why it is advisable to reduce or minimize the total lead time when it is possible.

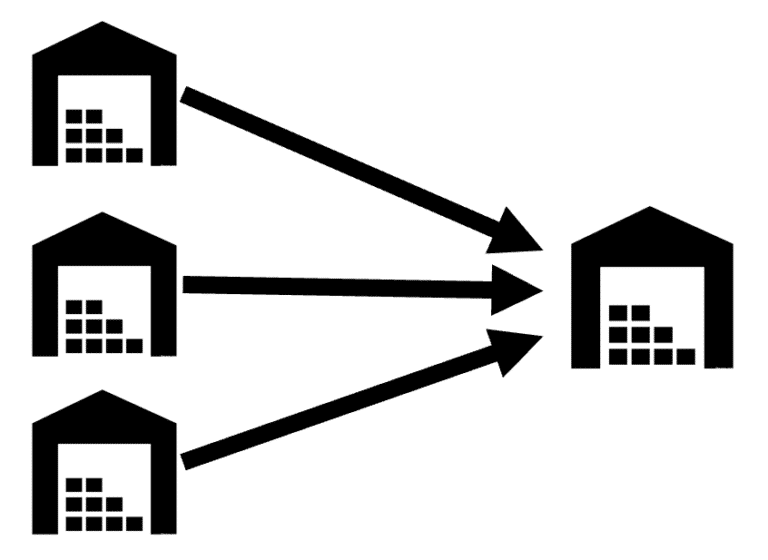

10) Centralize your inventory

I have worked with many different distribution networks in Europe, China and South America.

It is good to get a more decentralized network, with regionally based warehouses. This can reduce delivery times by getting closer to customers and optimize outbound transport in some cases. But, from my experience, it is very often better to stick with a centralized network.

Indeed, centralizing inventory allows to group orders and thus optimize inventory regarding MOQ quantities. In general, the more you have distribution facilities, the more complex it gets to manage and the higher are the inventory levels.

11) Automate your replenishment

The last inventory reduction strategy is to automate replenishment processes. Identify your most predictable products and automate the whole reorder procedure using your current inventory management software.

In Supply Chain, it is very important to focus your time and resources on what matters. Automating can save you a lot of time, so you can be more focused on decision-making.

Optimize Inventory: Action Plan

Here is my action plan to help you to Optimize Inventory:

- Pick one of the 11 inventory reduction strategies. If you don’t have indicators or proper product classification, start with KPIs and ABC Analysis, as they will be the foundation of your analysis.

- Implement this solution today.

- Track performance, and quantify results.

- Keep it simple and iterate.

What’s important to remember from this article

How can I start optimizing my inventory without complex tools?

Begin by tracking a couple of key metrics. You don’t need dozens of KPIs — just make sure you measure service level (like Fill Rate or Availability Rate) and Inventory Turnover. Without data, it’s impossible to improve. Keep it simple but consistent.

What is the 80/20 rule and how does it apply to inventory?

It’s called ABC analysis. Basically, 20% of your products generate 80% of your results. So stop treating all your SKUs equally — focus on the few items that matter most (A items), manage the B group carefully, and don’t overinvest in the C group. It’s common sense, but too often overlooked.

What should I do with slow and obsolete stock?

First, identify them. Then act. Cancel POs, push for returns, run promotions, or donate them — but don’t let them sit forever. Many businesses forget they even have dead stock, and that hurts both cash flow and warehouse space. Act now, not next quarter.

Is it okay to have stockouts sometimes?

Yes, especially for low-selling products. Trying to reach 100% service rate for every SKU is not realistic. Accepting shortages for C items can free up working capital and reduce waste. Think strategic, not perfectionist.

Do I really need to reduce my product range?

Often, yes. A huge product portfolio creates complexity, cost, and slower stock turns. Look at Apple — limited SKUs, massive sales. Simplifying your catalog can help you boost availability on the items that matter and avoid fragmentation of your stock.

Become an Inventory Management Expert

If you want to go to the next level, join my next Inventory Management Workshop (free): “How to avoid shortages and overstocks in times of great uncertainty”.

During this webinar, I will share with you:

- My method for dealing with sales and supplier uncertainty: 13 parameters to master

- How to reduce your inventory and increase your service rate simply and automatically

- Excel files and case studies presented live (Zara, H&M, Amazon…)