To be effective in a field such as the supply chain, it is first and foremost necessary to understand its fundamentals and operating principles. So, what is Supply Chain Management?

What are its fundamental principles? How does inventory management work? If you are wondering what the Supply Chain Management really is, this article is here to enlighten you.

What is Supply Chain – The different flows:

Briefly, the supply chain management is divided into 3 flows:

The physical flow of the Supply Chain:

It can be associated with logistics, i.e. the movement and storage of goods. We start from a production site, then probably move to one or more warehouses, then to a store or a final customer. This physical flow is really based on the transport and storage of the flow of goods.

The information flow of the Supply Chain:

It is the brain that will make the physical flow work. It is like a gigantic database that could be summarized by the following questions:

- What? (all processes and associated information)

- Where? (in which country, in which warehouse in which store but also in which IT systems)

- How? (by what means and under what pre-established conditions)

- When? (throughout the entire product life cycle). It includes, for example, all the recorded characteristics of a product, all sales history, all your performance indicators but also all the information on your suppliers that can affect your procurement strategy.

The challenge of this information flow is to know how to use it to predict and anticipate the future. If you can establish what will happen in the future, the work of the supply chain teams is simplified.

In addition, logistics also has information flows, so in the end, the physical flow and the information flow are closely linked. To optimize logistics movements within a warehouse, for example, a large flow of information is required to improve process and productivity.

The financial flow of the Supply Chain:

It can also be considered as information and is similar to all money movements to partners, suppliers, and subcontractors, as well as within your company. Money flow is a procurement strategy in its own right. In large companies, this flow is carried out in several currencies. And the strategy employed to move these currencies between suppliers and the company is fundamental and a factor of failure or success.

Several people within the company are involved in the supply chain management. They oversee all procurement, inventory forecasting, IT management, and financial forecasting.

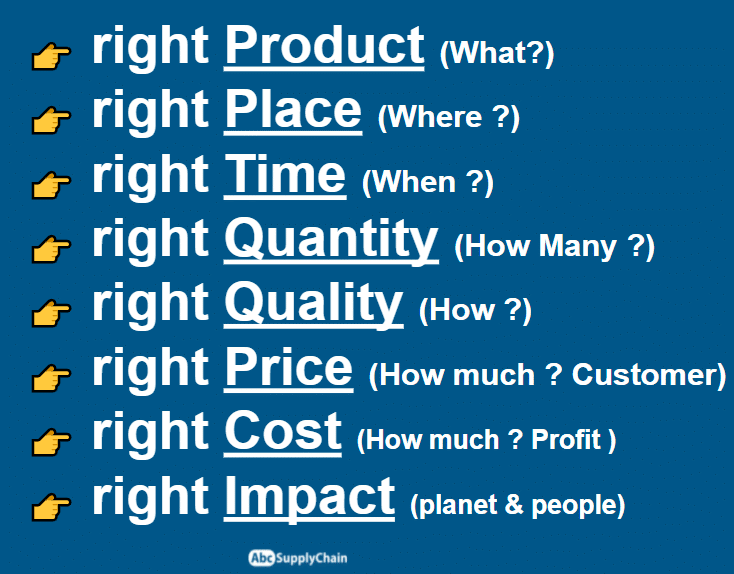

Finally, the goal of the supply chain is to make its products accessible at the right time, in the right place, and at the best price. This is achieved by having the most efficient supply chain possible.

To do this, it will, therefore, be necessary to find a balance between the satisfaction of your customers and the profitability of your company. To achieve this, it will be necessary to be as precise as possible in inventory management for example (owning an infinite stock is obviously not possible).

What is the Supply Chain’s goal?

The supply chain and its series of streams are there to make sure that you have the:

What is Supply Chain Management? An example: the journey of a tee-shirt

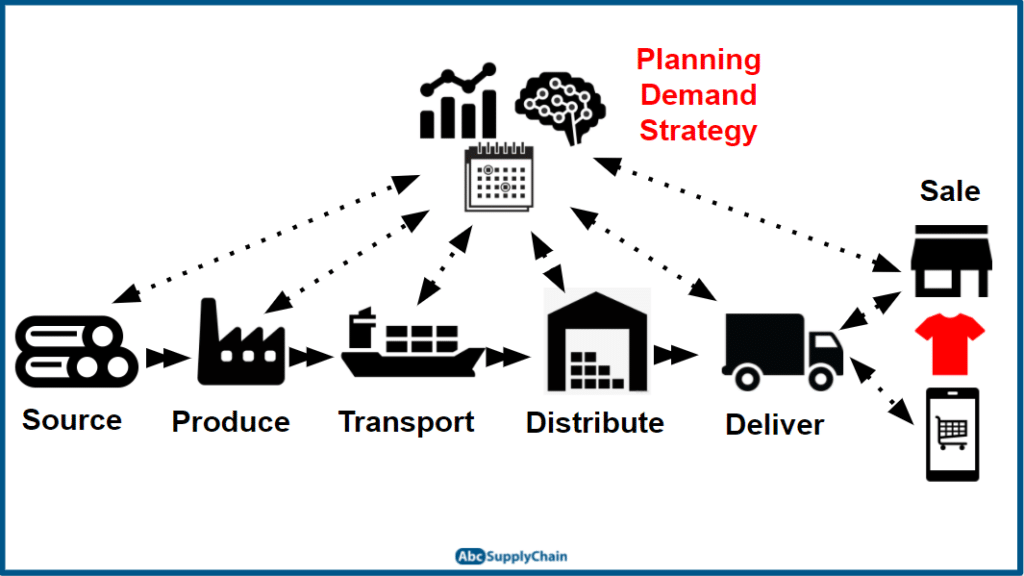

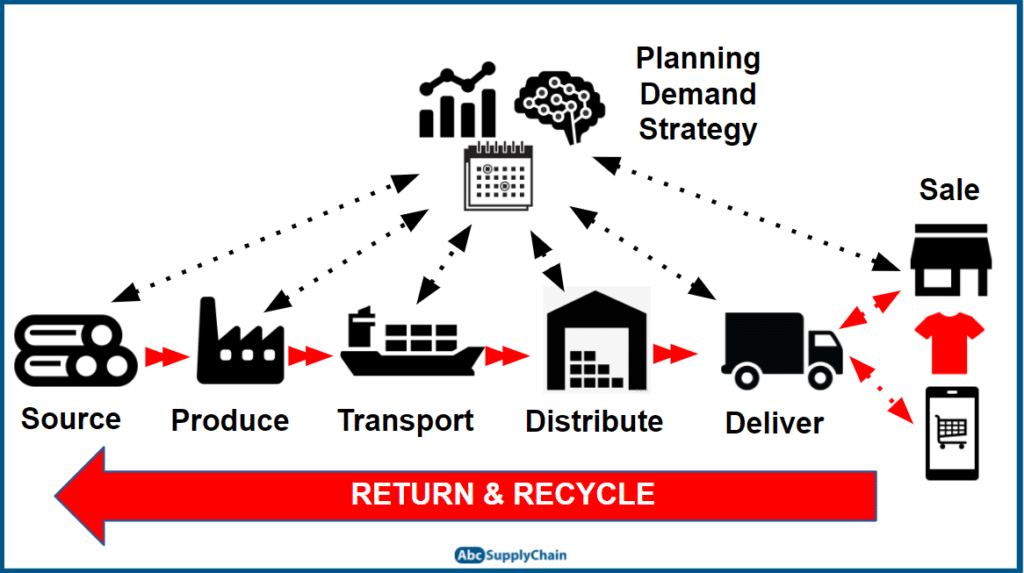

Forecast & Demand Planning

Selling something as simple as a red tee-shirt requires careful planning. It isn’t just a case of deciding to sell an item on a platform – you need a strong strategy to make sure you can coordinate all steps of the supply chain. It is therefore essential to work on effective forecasting.

First, there are essential questions you should ask yourself before selling a product. You must decide what kind of product you wish to sell – this tee-shirt also comes in blue, yellow and green, etc. Which color will you choose? Where do you want to sell it? How many would you like to sell? When would you like to sell it?

Read also : our best inventory management tips, tools and articles

Procurement & Purchasing

Once you are clear on what you wish to sell, how many pieces and, when you are going to sell it, it is time to talk about sourcing the raw materials. Let’s think about our tee shirt: what kind of cotton do you want? Where should you source it? At what cost? How much of it? When? What is the impact of your purchase on the planet?…

Manufacturing

Where will you produce these tee shirts? Do you outsource to China for a lower cost but a much longer lead time or keep production at home, even though the cost is higher but the lead time and minimum order is lower? Do not forget to question your manufacturing process, your quality process, etc. to ensure that you have got all the boxes ticked at this point in time ✔.

Transportation

It’s time to ship your product to your warehouses and your customers! Once more, ask yourself the right questions. How will you ship these? What mode of transportation will you prioritize? How much will this cost you and the earth? How much will you ship at a time? What is the lead time?

Taking time to plan ahead of purchasing your products is extremely beneficial. It gives you peace of mind and time to foresee all of these costs, to make the most profitable decisions for you and your business.

Distribution & Warehousing

Congratulations! Your tee shirts are now safe and sound in your warehouse or distribution centers. Time to wonder how you will organize this stage of the supply chain. Where will be your distribution centers? How will you pick, pack and ship these products to where will they be sold?

Delivery

Once your products are ready to ship, they must be delivered (to a store or directly to the customer). Many decisions must be made again: how often will you deliver? What type of vehicle will you use? How can you optimize your profit and the satisfaction of your customers at this stage?

Sales to the consumer : retail and ecommerce

As we reach the end of the chain, it is time to sell the product. Here again, you will face many choices. How and where will you sell? Online? In a physical shop? What will be the cost of your product? According to the stock that you have, should you think about doing a promotion?

Reverse logistics : return and recycle

We cannot ignore the impact that our businesses have on the planet and this part of the supply chain is becoming more and more important these days. When planning your sale cycle, think about returning and recycling your products ♻. How much will this cost? How will you recycle the product? etc.

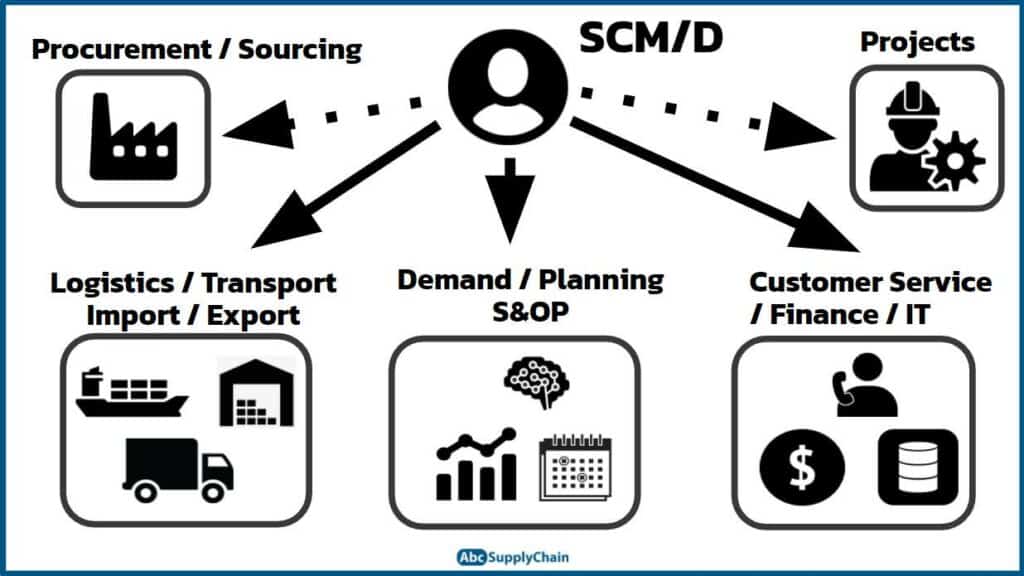

Supply Chain Jobs

In Supply Chain, there are hundreds of people working together to make sure that a product gets from point A to Z in time. The non-exhaustive list of jobs include:

- Logistics / Transport / Import / Export teams work on the physical stream of the Supply Chain.

- Demand planning and S&OP teams are responsible for forecasting, inventory management and coordinating all the different departments of a company with the sales and operation planning teams.

- Customer Service / Finance / IT teams split their time working on the information and the financial streams of the Supply Chain.

- Procurement and Sourcing teams have an impact all the way through the Supply Chain management.

- Project managers and consultants work on optimizing and improving all the processes and tools used by a company. I worked as a Supply Chain manager and Director for many years and if you would like to know how to become Supply Chain manager, follow my tips!

Supply Chain Challenges

Supply Chain professionals manage the flow of raw materials and goods in order to ensure the smooth running of the company.

One of the first challenges that you may face in the Supply Chain, is the various internal human resources that must be managed in order to get the most out of each position. And let’s not forget that there are external resources such as suppliers, warehouses, carriers, and warehouse workers. A good relationship must be maintained with the actors of each entity because good collaboration is essential.

Challenge number 2 involves the various services inherent to the proper functioning of the supply chain such as planning, packaging, handling, warehousing, export, transport, customs, invoicing, and disputes. The management of the elements necessary for these services must be ensured: storage infrastructures, warehouses, tools, machinery, vehicles, etc. must be taken into account.

The costs associated with the supply chain can also quickly get out of hand and simply drive down a company’s bottom line. The aim is to anticipate as much as possible any risks that may affect the system and cause unexpected additional costs. The company’s profit margin is therefore highly dependent on these costs.

Costs are also an integral part of the productivity objectives set by management. It is not uncommon for supply chain budgets to be huge to achieve these objectives. For these reasons, the supply chain manager often sits on the board of directors and must report the results of activities to the managers.

To summarize, a profitable Supply Chain must:

- Improve its service

- Reduce the inventory and cash invested in the business

- Keep the costs down

What is Supply Chain? Global-View

The image of efficiency and the quality of the service provided by the company in terms of delivery time, both to customers and suppliers, is also based on the quality of the supply chain.

The supply chain is also increasingly contributing to the ecological image that a company wishes to convey. The means of transport or raw materials used in the work processes of the supply chain can be promoted to give an environmental and sustainable image to the company, or on the contrary, have a negative impact if the means used are polluting for example.

What is Supply Chain Management’s future?

The future of the Supply Chain can be explained by two graphs :

This first graph comes from Google Trend, in which we have typed the word ‘Excel’. It shows that despite the digital transformation and the development of very advanced software, Excel remains an essential tool in the management, analysis, and improvement of the supply chain and will therefore probably remain so for a few years. Overall, it is used by 98% of companies. Start your Excel training today to become an expert !

This second graph shows trends involving keywords that revolve around data management: Big Data, Machine learning, Data Science, Deep learning. There is an explosion in the volume of research on data processing, collection, and analysis. This data becomes fundamental to analyze and improve the entire quality of the supply chain. Today, 98% of companies still use Excel, but most of them use it in a very basic way.

Nevertheless, the gap is widening between traditional companies and those that place data intelligence at the heart of their strategy. The objective for most is, therefore, to move from traditional management to intelligent supply chain management. For example, Amazon is investing in this area and into artificial intelligence to make it possible for everyone to use machine learning and deep learning.

The supply chain is strongly impacted by these new technologies. The data becomes usable in real-time, which results in a faster workflow, i.e. the production process.

FAQ – Understanding Supply Chain Management

What are the main flows in Supply Chain Management?

Supply Chain Management encompasses three primary flows:

- Physical Flow: Involves the movement and storage of goods from production sites to warehouses and ultimately to customers.

- Information Flow: Pertains to data related to processes, locations, methods, and timelines, enabling effective forecasting and decision-making.

- Financial Flow: Relates to monetary transactions with partners, suppliers, and subcontractors.

What is the primary goal of the supply chain?

Key coThe main objective is to make products accessible at the right time, in the right place, and at the best price by ensuring an efficient supply chain.

mponents include planning, sourcing, production, logistics, and returns.

Who is involved in managing the supply chain within a company?

Several roles are involved, including those overseeing procurement, inventory forecasting, IT management, and financial forecasting.

How does supply chain management contribute to a company’s ecological image?

The supply chain can enhance a company’s environmental reputation through choices in transportation methods and raw materials, promoting sustainability.

Become an expert in Supply Chain Management now!

Now that you know more about Supply Chain and its many aspects, it is time to get trained and develop your career in Supply Chain with us at ABCSupplyChain. Enjoy our methods now and boost your skills, your performance, your income, your energy, and more importantly, your freedom as you become a Supply Chain expert.

What is Supply Chain? Want to know more?

If you want to go further in your research about what exactly is Supply Chain, check out these articles: