I. A Ground-Level Survey of 317 Forecasting Professionals

We surveyed 317 professionals working in demand forecasting roles worldwide, and their responses offer a raw, honest look at what’s working, what’s not, and what they wish they had.

Our respondents represent:

- 72 countries — with France, the U.S., India, Morocco, and Canada among the most represented

- 20+ industries, including:

- Manufacturing

- Retail & Distribution

- Consumer Goods (FMCG)

- 13 job categories, from frontline employees to consultants, directors, and VPs

Whether they’re managing planning in a factory or optimizing inventory at scale, they all have one thing in common: they forecast demand — often in complex, uncertain environments.

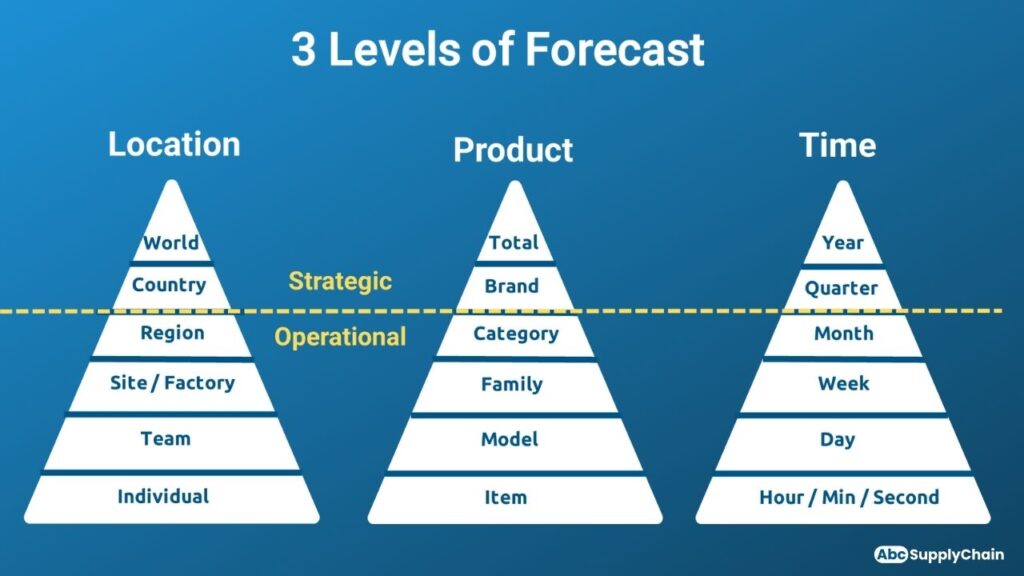

What Types of Forecasts Are They Managing?

We asked: “What type of demand forecasting are you managing today?”

Here’s what came out on top:

- Item/Product level forecast: 113 respondents

- Financial forecasts (P&L, budgets): ~40

- Activity forecasts (warehouse, factory, teams): ~36

- Global-level forecasts (company or BU level): ~15

- Mixed setups (SKU + financial + activity): many respondents handle multiple types at once

This reflects the reality of many planning teams today: forecasts aren’t siloed. They’re cross-functional and interconnected.

II. The 5 Most Common Demand & Sales Forecasting Challenges

When we asked 310 professionals, “What is your biggest challenge today in demand forecasting?” we didn’t get vague answers. We got detailed frustrations from the field — raw, honest, and globally consistent.

After analyzing hundreds of responses, five core challenges stood out:

1. Forecast Accuracy is Poor and Everyone Knows It

“Our main challenge is the accuracy due to unpredictable demand on some items.”

— Employee, Manufacturing

“The forecast that we receive from sales team in almost segments are very inaccurate.”

— Manager, Manufacturing

Many companies struggle with forecast accuracy, and the reasons vary: poor historical data, changing customer behavior, new product introductions, and volatile markets. But the result is the same: low confidence in the numbers and reactive firefighting down the chain.

2. Collaboration is Siloed or Nonexistent

“We are facing challenges in collecting data from different departments.”

— Planning Manager, Electronics

“Not everyone is aligned on the importance of forecasting, so we lack input from key stakeholders.”

— Supply Planner, Cosmetics

Forecasting isn’t a spreadsheet activity — it’s a cross-functional process. And yet, many teams still operate in silos, with little alignment between departments. This lack of collaboration leads to disconnects, conflicting assumptions, and poor decision-making.

3. The Process is Either Too Rigid… or Nonexistent

“We don’t have a proper forecasting process in place. It’s more of an ad-hoc activity.”

— Supply Chain Manager, Automotive

“We lack a structured methodology. Everyone uses different assumptions and timing.”

— Demand Planner, FMCG

Some companies have no structured process at all. Others have over-engineered systems that fail to adapt to market shifts. In both cases, the lack of a clear, agile framework makes it hard to deliver accurate, actionable forecasts.

4. Data is a Mess: Incomplete, Outdated, or Scattered

“Our historical data is inconsistent. We had a change in ERP and lost visibility on promotions and seasonality.”

— Head of Demand Planning, Pharma

“Data is scattered across tools and formats. It takes hours to consolidate before even starting the forecast.”

— Forecast Analyst, Retail

Bad inputs lead to bad forecasts. Many respondents cited fragmented data systems, poor data hygiene, and a lack of transparency as key blockers. The challenge isn’t having enough data — it’s making it usable.

5. The Tools Aren’t Helping (or Don’t Exist)

“We use Excel because the forecasting module in our ERP is too rigid and doesn’t fit our business model.”

— Supply Chain Manager, FMCG

“We’ve had a forecasting tool for 3 years, but it’s not used consistently. People don’t trust the output.”

— Planning Lead, Automotive

Tools are supposed to simplify forecasting. Instead, many respondents report overcomplicated software that doesn’t reflect how people actually work. Others still rely entirely on spreadsheets. The gap between what’s available and what’s used is wide — and growing.

III. What Forecasting Professionals Say They Need Most

After hearing about the challenges, we asked a more constructive question:

“What do you need most urgently to improve your demand forecasting process?”

Here’s what 310 professionals told us — loud and clear.

1. Better Data Quality and Structure

“If the base is incorrect, the entire process is wrong. We need better quality data, clean history, and better categorization.”

— Forecasting Lead, Consumer Electronics

“The main challenge is not the tool but the input data. Inconsistent formats, missing historical data, and lack of promo tracking.”

— Demand Planner, Food Retail

A large number of respondents emphasized the need for more reliable and better-structured data. Without it, even the best tools or methods fall short. Data visibility, standardization, and integrity are foundational.

2. A Clear, Structured Forecasting Process

“The process is not structured. Each region forecasts differently, and there’s no clear calendar or ownership.”

— Global Planning Manager, Industrial Sector

“We lack a clear forecasting methodology. People rely on intuition more than structured models.”

— Demand Analyst, Cosmetics

Respondents asked for clarity. A process that outlines responsibilities, timelines, inputs, and decision-making rules — not just a cycle that happens each month because it has to.

3. Cross-Functional Collaboration

“Sales and supply chain have different priorities. We forecast separately and then argue about whose number is ‘right’.”

— S&OP Manager, Consumer Goods

“We need one collaborative forecast. Finance, sales, and operations should all be involved from the beginning.”

— Planning Coordinator, Retail

The demand for more collaboration is strong. Forecasting isn’t just a technical challenge; it’s an organizational one. Breaking silos and encouraging shared accountability is essential. Those quotes exactly match the ones we had in our S&OP survey.

4. Tools That Actually Work

“We use a very powerful software… but no one really understands how to make it work for our real-life needs.”

— Head of Demand Planning, Healthcare

“Our tool is too complex for users outside of planning. It becomes a bottleneck instead of an enabler.”

— Forecasting Manager, Distribution

While not everyone asked for new software, many expressed a desire for tools that are usable, simple, and integrated with their existing systems. Flexibility, accessibility, and adoption matter more than advanced features.

5. More Time and Support

“I’m alone managing over 500 SKUs. I have no time to analyze trends or optimize the process.”

— Supply Planner, Fashion Industry

“We’re expected to improve forecast accuracy, but we don’t get additional support or training.”

— Demand Forecaster, Pharma

Many professionals simply lack the bandwidth or support to build a robust forecasting process. Without investment in people and time, forecasting stays reactive — not strategic.

IV A Practical Approach to Forecasting

If we learned one thing from this survey, it’s that reliability doesn’t come from software alone: it comes from structure, ownership, and discipline.

The good news? Most forecasting teams don’t need to rebuild everything. In fact, many improvements can happen with the tools they already have — and without any new budget.

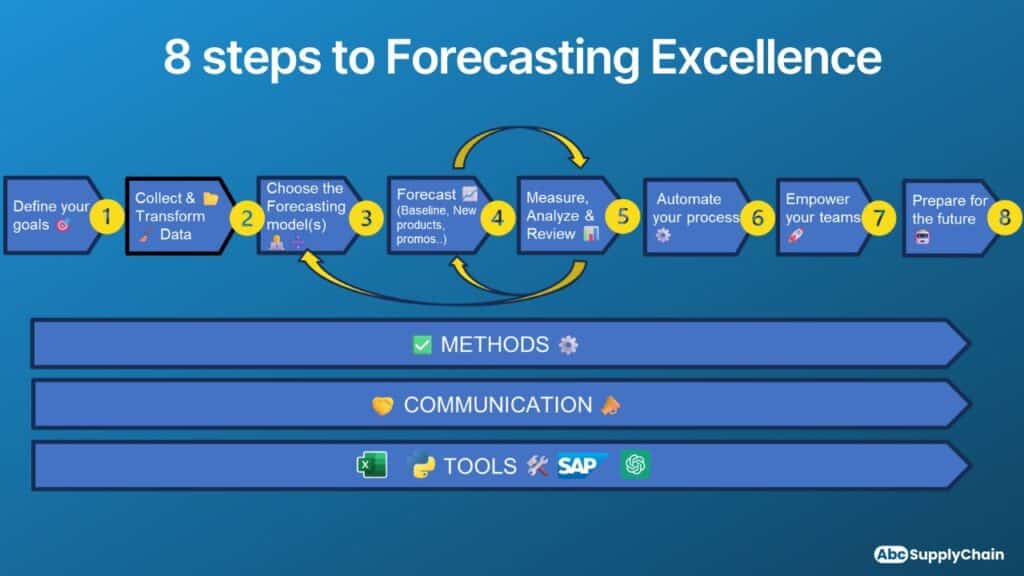

The best-performing teams don’t just “run a forecast.” They follow a clear end-to-end cycle — from data to decision — that everyone understands. Here’s a practical roadmap inspired by the 8-step framework of our Forecasting Expert method.

Step 1: Define Your Goals

Start by asking the right question:

What do we want to forecast — and why?

Is your goal to plan procurement? Improve financial visibility? Optimize workforce planning? The answer will shape every step that follows.

Step 2: Collect & Transform Your Data

Forecasts are only as good as the data behind them. This means:

- Centralizing demand signals (sales history, promotions, returns…)

- Cleaning and transforming the data into a usable format

- Making sure it’s consistent, complete, and trusted

Step 3: Choose the Right Forecasting Method(s)

Don’t overcomplicate it. Depending on your business, this could be:

- A simple moving average in Excel

- A statistical model (exponential smoothing…)

- A hybrid approach for different product categories

Match the complexity of your model to the value it brings.

Step 4: Generate the Forecast

This is where combining historical data, assumptions, and intelligence (manual or algorithmic) can generate your baseline, promo, or new product forecast.

Step 5: Measure, Analyze & Review

Forecasting without feedback is guesswork. You need to:

- Compare forecast vs. actual

- Measure accuracy (MAPE, bias, etc.)

- Identify root causes of deviations

And most importantly: act on what you learn.

Step 6: Automate What You Can

Manual steps create risk and waste time. Automate recurring tasks like data refreshes, report generation, or forecast updates — starting with the low-hanging fruit.

Step 7: Empower Your Teams

A great forecast is useless if no one believes in it or knows how to use it.

Make sure:

- Roles and responsibilities are clear

- Teams are trained and involved

- There’s a culture of collaboration, not blame

Step 8: Prepare for the Future

Once your foundation is solid, the next challenge is to evolve your approach. That means pushing the boundaries of what forecasting can do for your business.

- Probabilistic forecasting to better manage uncertainty

- Machine learning: for practical use cases

- Forecasting at Amazon scale

- And how to avoid the common traps of “black box” AI

Bottom line

You don’t need fancy software to define a straightforward process. You need clarity, ownership, and discipline. Even with Excel, following these 8 steps will bring consistency, reduce firefighting, and turn forecasting into a true business enabler.

FAQ

What are the biggest challenges in demand forecasting today?

Many professionals struggle with poor data quality, low forecast accuracy, siloed collaboration, and tools that don’t reflect real business needs.

How can I improve my demand forecasting process?

Start by defining clear goals, standardizing your data, and creating a structured process. Empower your teams and focus on collaboration across departments.

What tools are best for demand forecasting?

There’s no universal tool — Excel, statistical models, or AI platforms can all work. What matters is alignment, adoption, and fit for your business context.

How do I structure an effective forecasting process?

Follow an end-to-end cycle like the 8-step framework: define goals, clean data, choose the right method, forecast, review, automate, empower, and future-proof.

Why is collaboration critical in forecasting?

Because disconnected forecasts from sales, finance, and operations lead to misalignment. A shared process with clear ownership improves both trust and outcomes.

Is software enough to improve forecasting?

No — software alone won’t fix poor processes or data. What makes forecasting reliable is structure, ownership, and discipline.