The role of a Demand Planner is one of the most strategic positions in the Supply Chain. And yet, many organizations still underestimate the importance of this role.

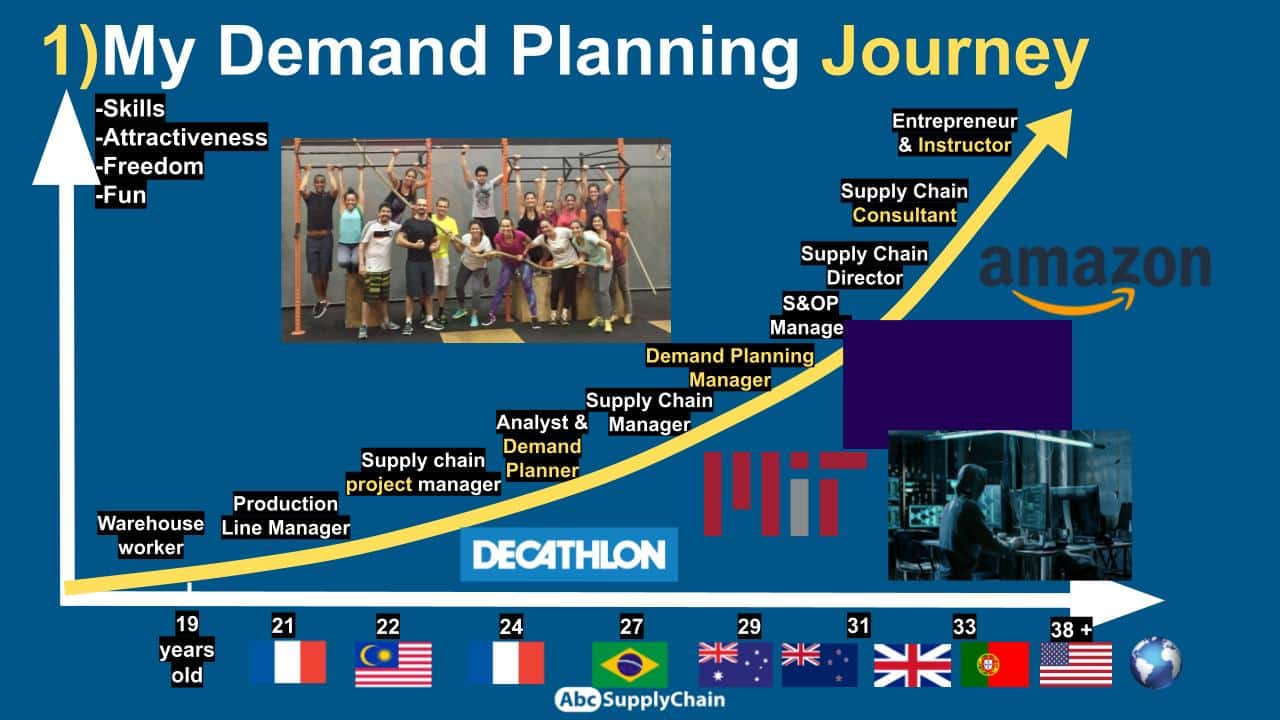

With over 15 years of experience as a practitioner, facilitator, and trainer in this field, I’m sharing here the 11 key steps that have shaped my vision of Demand Planning.

Why is this role so strategic? What skills are essential to master? What tools are used daily? How can you step into this role or excel if you’re already in it? What are the possible career paths before and after working in Demand Planning?

This profession is evolving quickly, career opportunities are booming, and salaries are rising. Through this article, I offer a practical and unfiltered look into the daily life of a high-performing Demand Planner—with methods, hands-on tips, and even a powerful shortcut to accelerate your growth in this high-potential career.

My experience in Demand Planning

I have built my professional journey around Demand Planning, through a variety of roles that have allowed me to explore all its facets.

- Project Manager, in charge of automating, simplifying, and improving demand forecasting processes

- Analyst & Demand Planner

- Supply Chain Manager, leading and managing teams of Demand Planners

- Demand Planning Manager

- Supply Chain Director

- Supply Chain Consultant, with a constant focus on forecasting and inventory management

For several years, I have also been a trainer and the founder of AbcSupplyChain, a training organization that supports professionals—both in French and English—from companies of all sizes worldwide. This role as an instructor allows me to share both operational know-how and strategic insights with a new generation of Demand Planners, at a time when this role is becoming increasingly central within organizations.

What does the Demand Planner do?

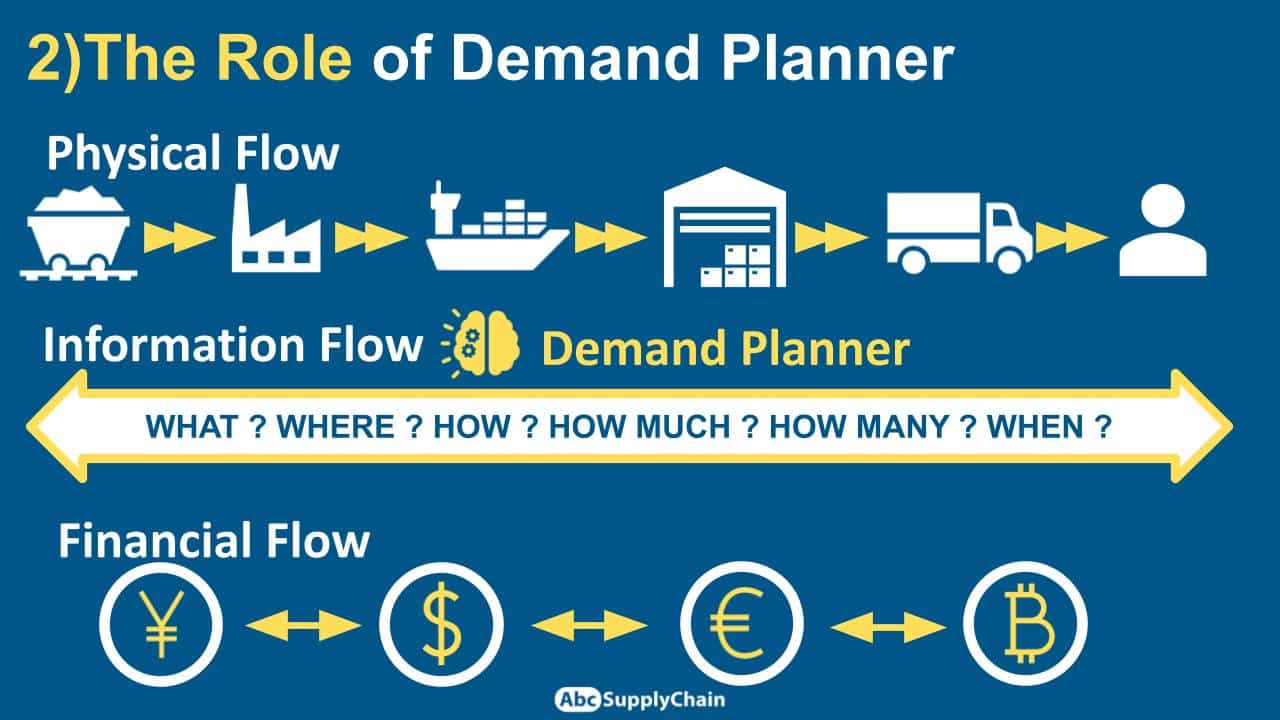

What does a Demand Planner do? To understand this role, you need to visualize the Supply Chain as a system that companies have built around three main flows :

- The physical flow: it involves transportation, storage and distribution of goods

- The information flow: it includes all aspects of planning, data, forecasting, and cross-functional communication to determine what to produce, how much, where, when, and how.

- The financial flow: this refers to the movement of money linked to sales, purchasing, and cash flow.

The Demand Planner plays a central role in managing the flow of information. He is responsible for turning data into actionable plans. Through his analysis, he supports planning, guides production decisions, optimizes inventory, and anticipates market needs.

In this way, he acts as a true conductor of the Supply Chain within his scope, working closely with sales, marketing, operations, finance, and sometimes even directly with customers.

Why is the Demand Planner role so strategic?

The demand planner’s strategic importance lies in his central role in the flow of information across the supply chain. Acting as a cross-functional coordinator, the Demand Planner interacts with a wide range of stakeholders. Depending on their scope, they may work closely with procurement and sourcing teams, as well as with production, logistics, or distribution.

In my teams, some Demand Planners oversaw the entire value chain — from suppliers to final distribution. That’s why I strongly advocate for a vertical approach to Demand Planning, which fosters a broader understanding of the supply chain and enables more coherent, effective decision-making.

Beyond its key contribution to business performance, this role is also appealing for very tangible reasons: salaries are attractive and rising steadily, mainly due to the shortage of qualified professionals and the increasing complexity of supply chain operations.

Demand Planning salaries

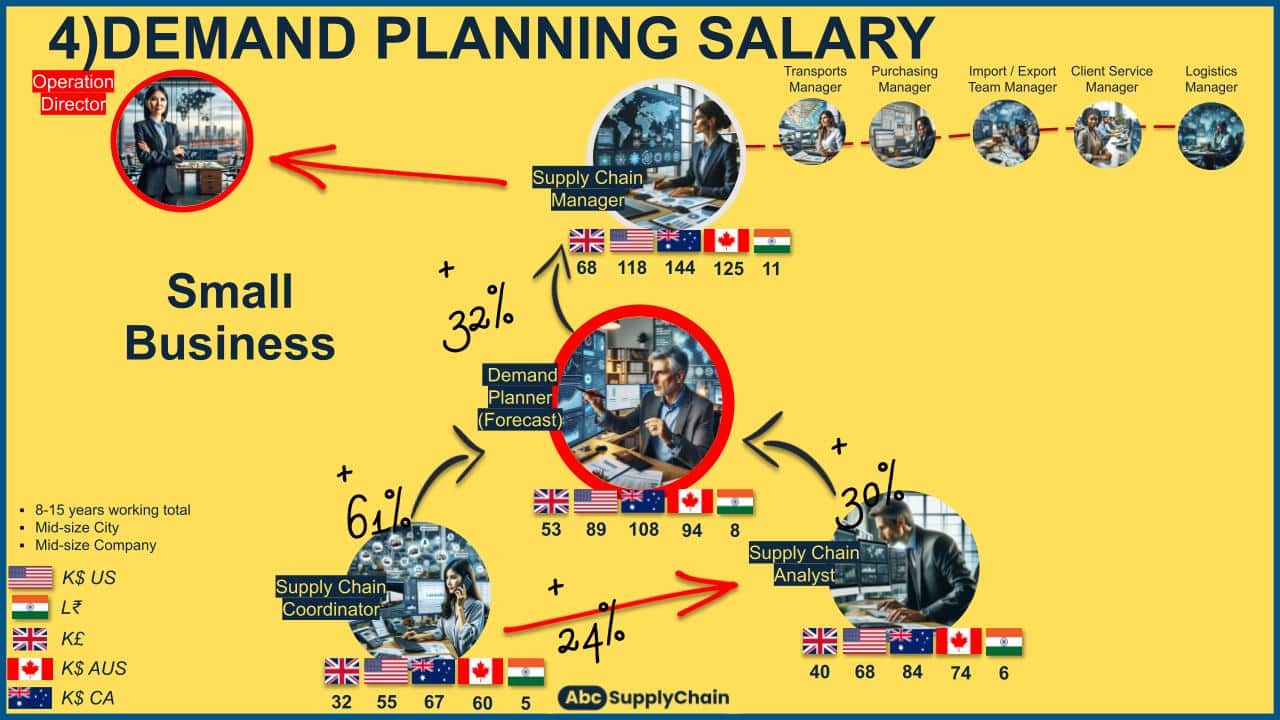

Demand Planning is not an isolated job. It relies on a true chain of complementary roles that allow for step-by-step progress and the acquisition of a global vision of the Supply Chain.

Some of the positions available before becoming a Demand Planner include:

- The Supply Chain Coordinator, who ensures the operational execution of the planning.

- The Analyst, who focuses on data, forecasts, and key performance indicators.

These roles are excellent stepping stones to the Demand Planner position, especially in large companies.

In smaller organizations, Demand Planners often have more versatile profiles, handling forecasting, inventory, and planning. They typically report to the Supply Chain Manager and already benefit from attractive salaries, even in mid-sized cities.

Over time (typically after 8 to 15 years of cumulative experience across different roles), these professionals move into strong, well-paid careers with clear advancement opportunities.

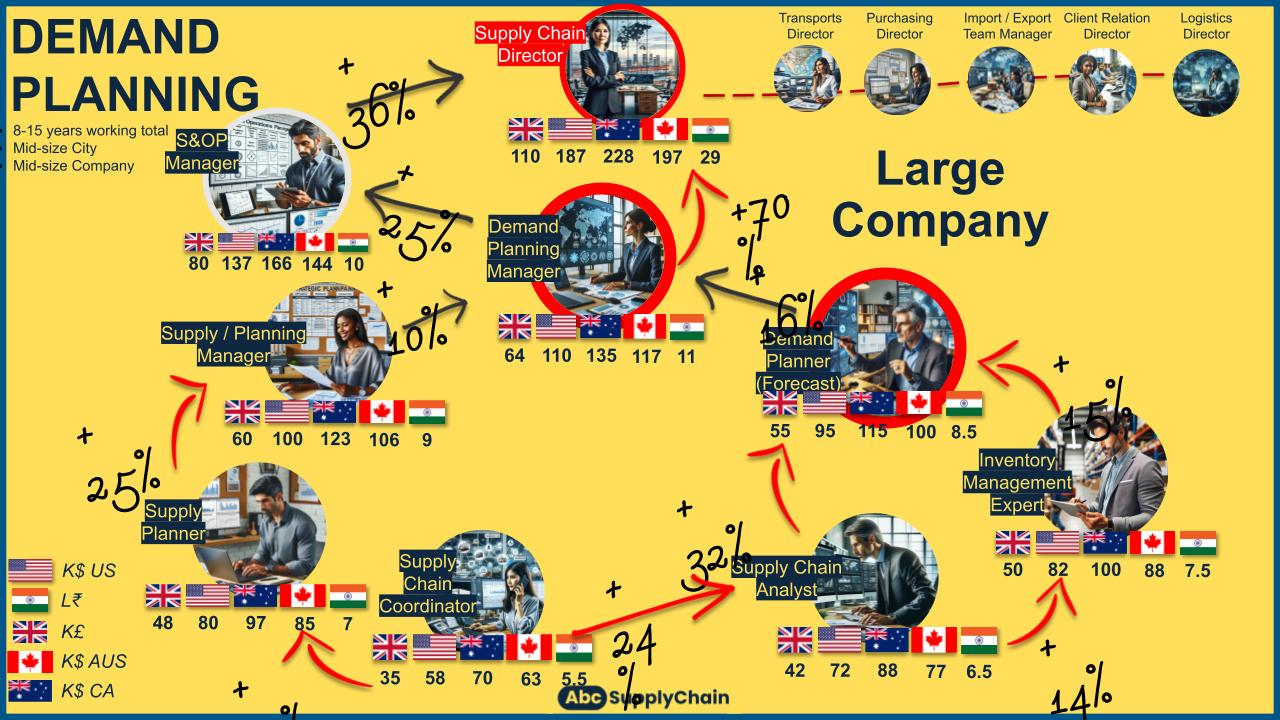

In large corporations, Demand Planning tends to be more specialized. For instance, during my time at Decathlon and Coty, the roles were segmented:

- On one side, planners (or coordinators) turned forecasts into operational plans for production, distribution, and transportation.

- On the other hand, analysts analyzed the data to improve forecast accuracy, optimize inventory, and streamline flows.

I’ve overseen demand planning operations across 2,000 stores and 60 warehouses, demonstrating that Demand Planning expertise can scale significantly.

Beyond the Demand Planner role, there are positions with broader responsibilities:

- Demand Planning Manager

- S&OP Manager

- Supply Chain Director

These roles build on the foundations of Demand Planning, adding a strong strategic and cross-functional leadership component.

If you’re curious about compensation, check out my article: Supply Chain Salary & Jobs: Ultimate Guide

The future of the Demand Planner role

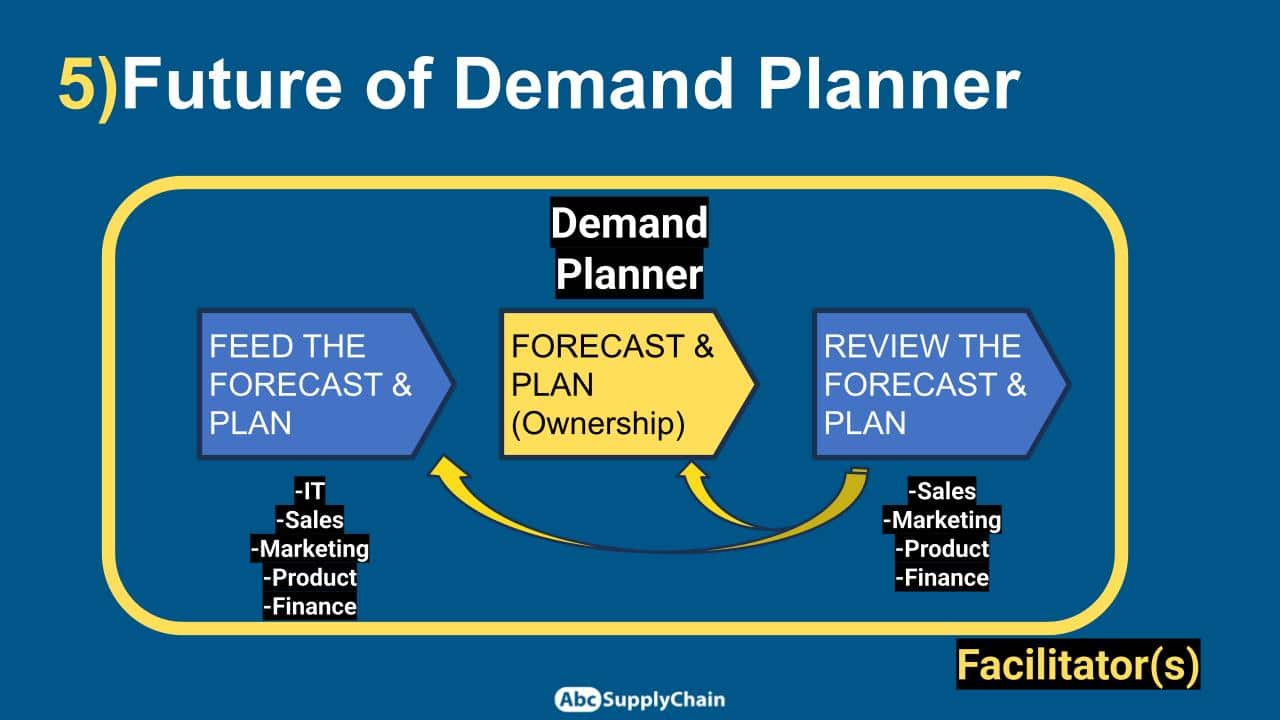

The Demand Planner thus becomes a true facilitator, a mini Supply Chain Manager or S&OP Manager within his scope. At Decathlon, for example, we had a dedicated Demand Planner for each product category: running, rackets, etc. Each of them operated as if they were the CEO of their domain, responsible for the overall performance of the flow.

The role of the Demand Planner has evolved rapidly in recent years. For example, it was previously referred to more commonly as “forecaster” in France, but today, it’s widely recognized as a key function in modern Supply Chains.

During a conference I hosted in Paris on the future of Demand Planning, I led a discussion with professionals on how the role is changing. One key takeaway: machines won’t replace Demand Planners but they are fundamentally reshaping their daily work.

Operational planning is becoming increasingly automated, especially in companies like Amazon. AI-powered predictive models already provide highly accurate forecasts. As a result, Demand Planners will spend less time crunching data and more time enabling cross-functional collaboration, leading S&OP processes, and feeding systems with high-quality inputs.

In this way, the Demand Planner becomes a true facilitator: a S&OP or Supply Chain Manager within their scope. At Decathlon, for instance, we had one Demand Planner per product category: running, rackets, etc., each operating as the CEO of their domain and fully accountable for end-to-end flow performance.

I’ve always encouraged this entrepreneurial vision of the role: empowering Demand Planners with the responsibility and visibility required to drive performance, refine forecasts, and coordinate cross-functional decision-making.

The future of this role lies in evolving into a highly strategic function that connects tools, data, and people.

How to Become a Demand Planner?

I often get asked: how do you break into Demand Planning without previous experience?

The good news is, there are clear, achievable pathways especially if you structure your development around six key pillars.

The 6 pillars to become a Demand Planner:

1. Acquire practical experience

Even if you’re not officially a Demand Planner yet, building relevant skills such as forecasting, inventory management, S&OP facilitation, data analysis, and cross-functional coordination is crucial.

2. Implementing the right tools and methods

A strong Demand Planner knows how to leverage tools (Advanced Excel, Power BI, ERP, APS, etc.) and apply proven methods to improve forecast accuracy, model demand, and size inventories effectively.

3. Develop Strong Technical Skills

Understanding forecasting models, performance KPIs, logistics flows, and capacity challenges is essential. You must speak the language of data—but also the operational language of the field.

4. Mastering interpersonal skills

A Demand Planner never works alone. They must know how to communicate, persuade, unite teams, lead cross-functional workshops, resolve conflicting objectives, and bridge departments. These are key soft skills.

5. Excel in your current role

No matter your current position, demonstrate a strong performance mindset and a drive for continuous improvement. This builds credibility and paves the way to more strategic roles.

6. Get relevant degrees or certifications

If you’ve never worked in this role before, specialized certifications (in forecasting, supply chain, APS tools, etc.) can reassure recruiters by showing that you’ve invested in developing expertise on complex topics.

Career Paths to Becoming a Demand Planner

Several key gateway roles can pave the way to a Demand Planner position:

- Supply Chain Coordinator

- Planning Specialist

- Data, Forecast, or Inventory Analyst

- Inventory Management Specialist

These positions help you build a strong foundation in flows, data, tools, and cross-functional processes.

If you come from a purely operational logistics background, transitioning directly into Demand Planning can be challenging without first developing strategic skills. That’s why I often recommend starting in an analyst or inventory specialist position, while actively developing the core skills required for Demand Planning.

Frequently Asked Questions About the Demand Planner Role

What is a Demand Planner?

A Demand Planner is a professional responsible for forecasting future product demand. They rely on historical data, market trends, and business inputs to optimize production, inventory, and availability.

What are the key skills of a Demand Planner?

A Demand Planner must master data analysis, Excel and ERP tools, cross-functional communication, forecasting methods, and have a solid understanding of the supply chain.

What are the 6 pillars to becoming a Demand Planning expert?

The six pillars are :

Gain hands-on experience closely related to the role (forecasting, S&OP, inventory, coordination, etc.)

Implement the right tools and methods to improve demand reliability and model inventory levels

Develop strong technical skills: forecasting models, KPIs, understanding of flows and capacity

Master interpersonal skills: communication, leadership, and the ability to bring people together

Perform well in your current role, demonstrating a culture of continuous improvement

Obtain targeted degrees or certifications to strengthen your credibility with recruiters

What’s the difference between a Demand Planner and a Supply Planner?

The Demand Planner forecasts future demand, while the Supply Planner plans procurement or production accordingly.

What tools does a Demand Planner use?

Excel, Power BI, SAP APO, Oracle Demantra, Anaplan… as well as forecasting modules integrated into ERPs

How can you train in Demand Planning?

Online courses like those from AbcSupplyChain help you build hands-on skills in forecasting, Su0026amp;OP, and inventory optimization.